|

![[In allestimento]](images/undercon.gif)

| |

Rotogravure (Roto or Gravure for short) is a type of

process, where an engraved cylinder transfer the images by direct pressure onto

an impression rubber coatet roller on the material to be print.

In rotogravure can be used different kind of inks:

| Solvent base |

| Water Base |

After the printing the ink, which is a mixture of pigments and solvents,

needs to be "dryed" , the drying process evaporate the solvents which

is the liquid component of the ink so only the "solid" color remains

on the web.

The Rotogravure process is mostly used for food packaging and

publishing

The most recent technologies of "laser engraving" the printing

cilynders enhanced the printing resolution which reach a quality similar to

Offset printing quality.

Typical substates to be printed in gravure are:

| Paper |

| Carrdboard |

| BOPP : Bi axially oriented polypropylen |

| PET : Polyester |

| BOPA: Bi axially oriented nylon |

| PVC |

| PE: polyetilene |

| Aluminium foil |

Laminates which are structures composed by two or more layers of different

materials according to the final applications

In the food packaing most of printed materials need to be laminated with

another layer of film or aluminum foil in two, three or four layers structure

according to the final applicaton of the packaging and barriers properties

required.

The different purposes of the printing material arte mainly

| Physical protection

- The food enclosed in the package may require protection from, among other

things, shock, vibration,

compression, temperature,

etc.

|

| Barrier protection

- A barrier from oxygen, water vapor,

dust, etc., is often required. Permeation

is a critical factor in design. Some packages contain desiccants

or Oxygen absorbers

to help extend shelf life. Modified

atmospheres or

controlled atmospheres are also maintained in some food packages. Keeping

the contents clean, fresh, and safe for the intended shelf life

is a primary function.

|

| Containment or

agglomeration - Small items are typically grouped together in one

package to allow efficient handling. Liquids, powders,

and granular materials

need containment.

|

| Information

transmission - Packages and labels communicate how to use, transport, recycle, or dispose of the package or product. Some types of information are required

by governments.

|

| Marketing - The

packaging and labels can be used by marketers

to encourage potential buyers to purchase the product. Package design has

been an important and constantly evolving phenomenon for several decades. Marketing

communications

and graphic design

are applied to the surface of the package and (in many cases) the point of sale

display.

|

| Security -

Packaging can play an important role in reducing the security risks of shipment. Packages can be made with improved tamper resistance

to deter tampering and also can have tamper-evident

features to help indicate tampering. Packages can be engineered to help

reduce the risks of package pilferage:

Some package constructions are more resistant to pilferage and some have

pilfer indicating seals. Packages may include authentication

seals to help indicate that the package and contents are not counterfeit.

Packages also can include anti-theft devices, such as dye-packs, RFID

tags, or electronic

article surveillance

tags, that can be activated or detected by devices at exit points and

require specialized tools to deactivate. Using packaging in this way is a

means of retail loss

prevention.

|

| Convenience -

Packages can have features which add convenience in distribution,

handling, stacking, display, sale, opening, reclosing, use, and reuse.

|

| Portion

control - Single serving packaging has a precise amount of contents to

control usage. Bulk commodities (such as salt) can be divided into packages

that are a more suitable size for individual households. It also aids the

control of inventory: selling sealed one-liter-bottles of milk, rather than

having people bring their own bottles to fill themselves. (source

Wickipedia) |

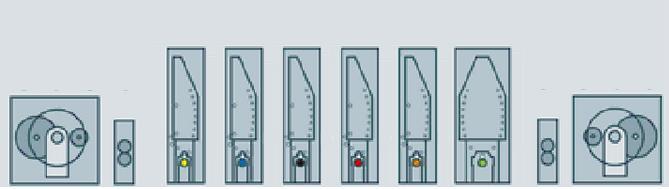

Rotogravure typical machine configuration

|